Applying Lean and Six Sigma tools, techniques and thinking to environmental problems is a fairly new concept. The U.S. EPA launched a Lean initiative that included free toolkits in the mid-2000’s, but the effort lost momentum over the years. However, there were some case studies put together over the years, and the results have been dramatic!

Get started with our FREE 4-part video series, See-Solve-Sustain to reduce environmental impacts using Lean and Six Sigma

If you’d like to check out some specific topics, check out these FREE downloads…

Eco Business Efficiency BoosterTM – A 6-step process to take waste and ineffieciency out of your office work to free up time for more valuable tasks. Eco Business Efficiency BoosterTM – A 6-step process to take waste and ineffieciency out of your office work to free up time for more valuable tasks. |

8 Ways Lean Six Sigma Can Reduce Environmental Impacts – Free case studies on how Lean Six Sigma has been used successfully to address environmental problems in different industries. 8 Ways Lean Six Sigma Can Reduce Environmental Impacts – Free case studies on how Lean Six Sigma has been used successfully to address environmental problems in different industries. |

40+ Environmental Lean Six Sigma Case Studies

40+ Environmental Lean Six Sigma Case Studies

Read one page summaries of over 40 environmental improvements from companies using Lean and Six Sigma techniques.

What is wrong with how we solve problems today?

When businesses and organizations attempt to reduce their solid/toxic waste, pollution, emissions, water and energy usage, it can often seem like a hindrance or a roadblock to their core business. Fearing a loss of profit or sales, they often look for ways to push the problem to someone else, sidestep or ignore the rules, leverage their influence to change the rules, or play with the numbers to show false improvements. The end result is that nothing actually improves, your relationship with them becomes combative or strained, and both sides are frustrated.

Even sustainable and ethical companies that are trying to do the right thing can get stuck. They have done all the “low hanging fruit” and don’t know what else to try. They are stuck in their current thinking, and their resources and money slowly get pulled back into their core business.

Lean and Six Sigma provides a new way of seeing and solving problems that can lead to an improved business and an improved environment. It doesn’t have to be a trade-off any longer!

Why Lean Six Sigma?

Here are some reasons why improvements using a Lean Six Sigma approach is better than your current approach:

• Can’t see all the waste today, so you don’t realize it’s there in the process, and it needs to be eliminated

• Focus on collecting data for use in solving and validating solutions

• Prevents sub optimization (pushing waste to other departments or people). It helps us optimize the system (systems thinking), not individual areas

• Instead of doing wasteful tasks more quickly, it will make you challenge whether it should be done at all (if it is “value added” or “non-value added”)

• Keeps focus on the customer at all times

• Although you have and can continue to save money and improve metrics using other approaches, you might be sabotaging your business by causing long term problems while trying to solve problems in the short term.

• Engages all employees in solving problems, which creates more ownership, and leads to increased productivity and engagement in the long run

• Go and see approach leads to better problem solving and solutions, and shows employees that you really care about their issues and problems

• Statistical analysis leads to better problem solving and solutions, by proving the improvements are real, not random chance

• Can generate fast and dramatic improvements using event approach (2-5 day kaizen)

• Solutions can be counter-intuitive (one piece flow, reduced multitasking, sub optimization, pull, problems first culture, etc)

• Approvals and buy-in are greater and faster with cross-functional approach, by getting everyone focused on the customer

• Methodical approach to making improvements (kaizen, VSM, DMAIC, PDCA, etc)

How does it work?

In a typical improvement event or project, a cross-functional team is brought together to review the current situation (through data collection and hand-on observations) and everyone on the team provides input, and the whole team agrees upon the actual problems going on. They discuss inefficiencies and identify sub-optimizations that are causing them extra work and frustration. These issues are captured and brought to the surface for all to see, and matched up with the data. A scientific approach is used to address the root cause of the problems, and structured tools and techniques of Lean and Six Sigma are applied to prevent recurrence of the problems, and identify when new problems arise. The best part is that all of this can be implemented in days and weeks, not months and years.

The result is engaged employees, stronger working relationships, and streamlined processes that have the customer first. This leads to new processes with less resources, performed in less time overall, with less labor and cost, and are completed with fewer mistakes and errors.

Lean and Six Sigma can be applied directly to environmental problems (such as an “Energy Treasure Hunt”), or can be applied to improve the core business of the organization or company (such as running experiments to optimize chemical usage), which will indirectly have a positive impact on the environment!

It creates a win-win, where they gain efficiency in their core business, and you get an improvement to the environment. This approach also helps you move from the “inspector” or a “supplier” into a trusted, long-term partner.

Sounds too good to be true?

You’re right, if it was this good, why are you just now hearing about it?

The majority of major corporations and businesses have some version of a Lean and/or Six Sigma program. From Toyota to General Electric to Boeing to Amazon (just to name a few), corporations looking to save money, speed up their response to customers and increase quality are far down this path already. Ask a friend who works in a manufacturing company if they know about Lean and Six Sigma. Most of them have, and many have been heavily trained in one approach or the other (or both). It just hasn’t made it’s way down to the environmental consulting, advocacy and not for profit organizations until now.

There is one catch. It’s a lot of hard work! Some of these companies are decades into their initiative, and still “just getting started.” In addition, some of the concepts are counter-intuitive (batch vs. one at a time, no more multi-tasking, pull vs. push, leaders work for the employee, problems are good, automation is bad, etc). And most importantly, if the leadership isn’t on board or if the deployment isn’t organized properly, it can become stagnant and fizzle away.

But the ones that get it right have achieved amazing results, and swear by the approach. When done correctly, it should change the fundamental way that the company is run (in a good way)!

Now that you understand how this approach can reduce waste and inefficiency by over 50%, you might be thinking of a few immediate reasons to increase your knowledge and experience with Lean and Six Sigma:

- You want to help your clients and customers become more efficient and effective, to get your “foot in the door”, and help them reduce their environmental impact

- You want to streamline and reduce frustration within your own organization, company or department to spend more time making a difference

- You want to make yourself more marketable to clients or future employers

In order to take your skills as an environmental professional and apply these powerful tools and new way of thinking, you’ll need some additional training and information.

If you’ve already downloaded the FREE PDF documents “Eco Business Efficiency BoosterTM” or “8 Ways Lean Six Sigma Can Reduce Environmental Impacts” or the 40+ Environmental Lean Six Sigma Case Studies, then the next topics are shown below.

- Free Lean Six Sigma and the Environment online course

- Not ready to take on an entire course? Start with “What is Lean and Six Sigma?” by watching these videos to teach you the basics

- Lean

- Focused on: standard work, organization, visual controls, waste, efficiency, customer value

- Improves: cycle time, response time, inventory, value, space availability, etc

- Six Sigma

- Focused on: variation reduction, statistical analysis, certifications, DMAIC, process controls, data monitoring

- Improves: quality, consistency, data accuracy, root cause analysis, prioritization, cost savings

- Lean Six Sigma for a Sustainable Future (LinkedIn Learning) – this 35 minute course is a great introduction to Lean and Six Sigma, and how it can be applied to Sustainability

- Lean

- Root cause analysis

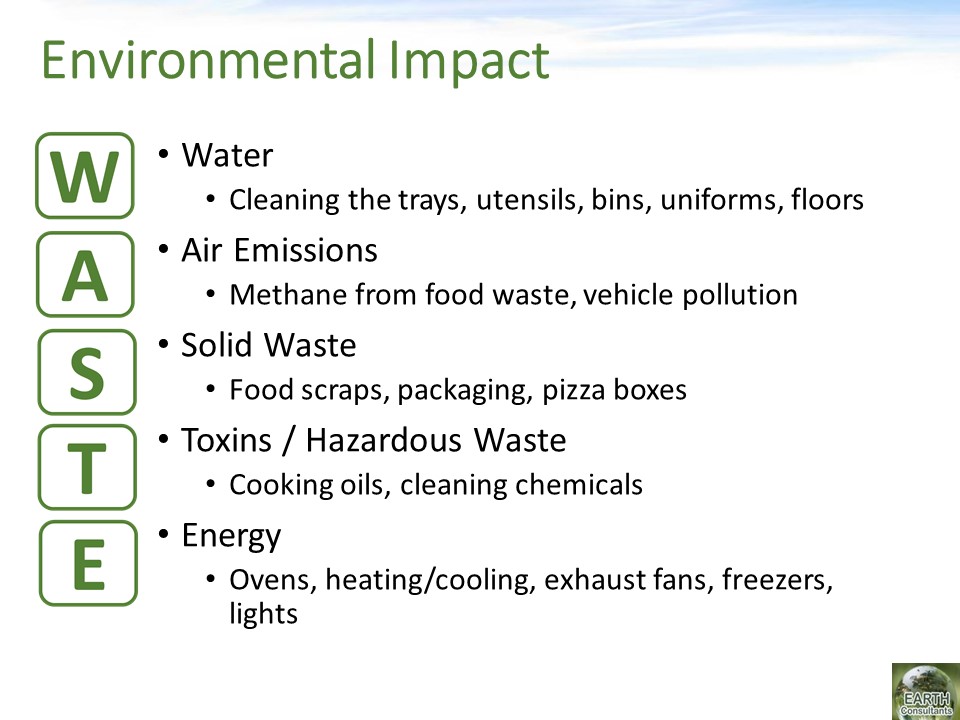

- Engagement of employees and stakeholders using WASTE Walks

- Change management

- Project Selection

- Training and certification options

- Lean Bronze, Silver and Gold

- Six Sigma Green and Black Belt

If you have some background in these tools already, you can already get credit for it by applying for our Earth Belt certification >>>

Do you have ideas how this could help my organization, company or clients?

Yes, there are a couple ways to get started. You can either run an improvement project or event. Here are some ideas to think about (but you can come up with your own as well, these are just thought starters…)

Events and Projects

- Combine processes into one standard process

- Install workplace organization

- Gather baseline metrics for a process

- Reduce cycle time of a process

- Setup system to visualize work-in-process or inventory

- Extract data and summarize results and findings

- Combine customer work into similar groups by processes (product/service family)

- Interview employees to collect improvement ideas

- Level out the customer demand

- Conduct a Go and See event

- Identify where the bottlenecks and constraints are in our process, and free up those resources

- Develop a high level process map for your work from customer back to supplier (VSM)

- Create a spaghetti diagram showing the walking and travel distance

- Perform timing studies to determine actual process time

- Move layout of work space to improve flow and make problems more visible

- Define roles and responsibilities between departments and groups

- Perform root cause analysis to resolve a problem

- Prioritize problems to determine which ones are most important

- Gather diverse group of people to brainstorm ideas and solutions

- Develop a cross-training matrix to determine which tasks and skills don’t have adequate backup resources (vacation, retirement, sick days, leave the company)

- Calculate and align process to keep up with customer demand

- Balance out workload to align with available resources

- Reduce setup time for process steps by over 50%

- Prioritizing customer needs

- Designing a new product with high quality manufacturing processes

- Identifying and prioritizing potential risks in a process

- Creating a process that highlights and identifies problems quickly

- Conducting a simulation to predict future results or performance

- Developing a plan to minimize resistance to change

Data Analysis

- Plan out survey questions for customer

- Setup data collection system

- Setup recurring reports and charts for management and process visuals

- Develop visual controls for daily performance

- Creating cost of non conformance (cost of errors) cost estimates

- Conducting an experiment to determine if the measurement system is reliable

- Calculating the probability that a process will achieve a given goal, based on historical data

- Detecting a trend or shift in a process

- Separating unusual data points (outliers) from typical results, both normal and non-normal data

- Creating metrics to track equipment utilization

- Determining which factors have the most influence on your metrics

If you still aren’t sure how to get started, contact us and we can discuss next steps, based on where you are at. We can apply certain tools for a specific task, help you plan or conduct a project or event, help with data collection or analysis, or provide an external (outsider) viewpoint.

If there is something we forgot. We also offer training on these topics, if you would like classroom or online training. Contact us for more information.