Solving Environmental Problems with Lean Six Sigma (Earth Consultants 2-Day Intensive)

SOLVING ENVIRONMENTAL PROBLEMS WITH LEAN SIX SIGMA

PORTLAND, OREGON

There are no live classes currently scheduled, but we have released the first part of this class for free online!

Lean Six Sigma and the Environment >>> (free!)

About the live class

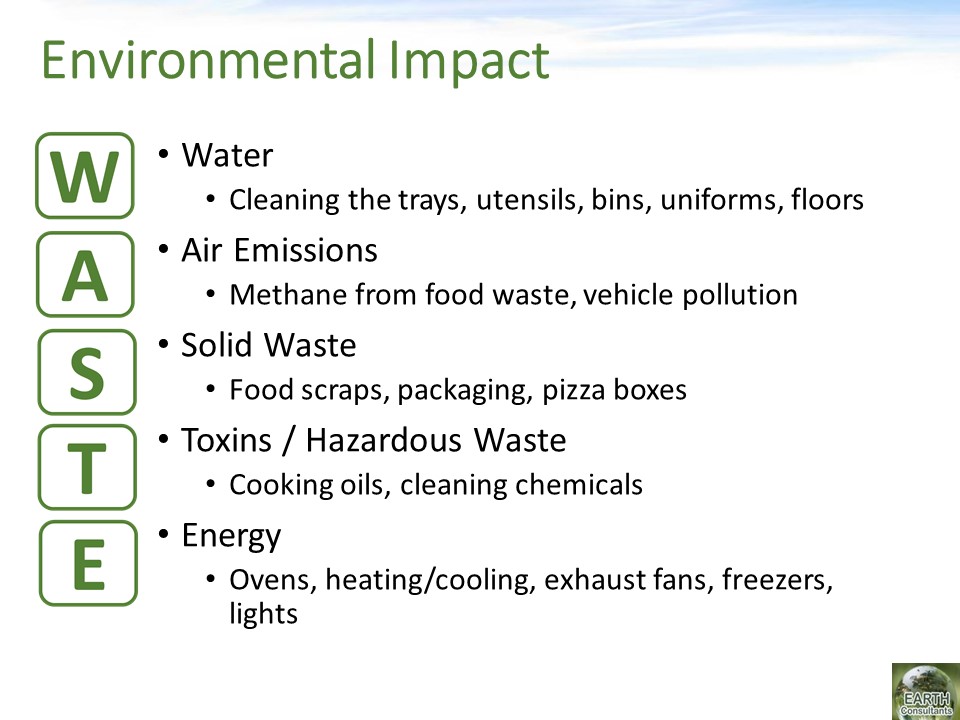

The 2-day class will cover the 3 step process for reducing environmental impacts with your clients, or within your own organization. This approach can work for any type of problem, but our examples and focus will be on the 5 types of environmental W.A.S.T.E. (Water, Air Emissions, Solid Waste, Toxins, and Energy). A 1-day version of the class is also available.

We will cover each of the 3 steps in great detail, providing examples of how each tool or concept applies.

After taking the course, you will feel confident in your ability to understand the See, Solve, Sustain framework, and determine what gaps you have in being able to follow this approach in your organization or with your customers or clients.

If you are new to Lean and Six Sigma concepts, we cannot make you an expert after just two days, but through practice and support from us, you will be able to make a huge impact on the environment.

If you have Lean or Six Sigma experience already, you will be in a great position to quickly adopt what you learn into your current projects and events, and open your eyes to additional wastes and costs that you may be overlooking today.

This approach will work with companies and agencies at any phase of their environmental journey, whether they are just getting started, or already industry-recognized for their stewardship.

Attendees will receive an electronic certificate of completion.

Looking for some examples? Download our “8 Ways Lean Six Sigma Tools Can Reduce Environmental Impacts” or our list of “40+ Environmental Lean Six Sigma Case Studies”

Here is an overview of each of the 3 major steps that will be taught in the course

|

Step 1: See

Step 2: Solve

Step 3: Sustain

|

Within each step, we will take about the following concept, tool or technique

Step 1: SEE

- Overview of See, Solve and Sustain

- Motivation to improve

- Case Studies

- 5 lean principles

- 8 Forms of Waste

- Environmental wastes

- Identify your value stream

- Go and See (W.A.S.T.E Walks or Gemba Walks)

- Energy Walk, Water Walk, Dumpster Dive

- Current, Ideal and Future State

- Problem Statements

- Process Management

- Clarify the problem

- Change Management

- New Tools (Green Impact Matrix, Green Systems Boundary Map, Water Balance Map)

Step 2: SOLVE

- Process Mapping

- Data Collection Tools

- Personal Time

- Easy Improvements

- Simple experimentation & split testing

- Problem Solving Models (PDCA, 8-Step, DMAIC, A3)

- Event types (kaizen, projects, bursts)

- Kanban

- Supermarkets

- Theory of Constraints (TOC)

- Single piece flow

- 5S workplace organization

- Value Stream Mapping (VSM)

- Cellular flow

- Communications boards

- Root Cause Analysis Tools (5 Why’s, Fishbone, Pareto, Graphical Analysis)

- 3P (with biomimicry)

- Common vs Special Cause (Capability, Variable and attribute control charts and SPC)

- Risk Analysis (Brainstorming, Failure Modes and Effects Analysis)

- Measurement System Analysis (Gage R&R, Attribute Agreement Analysis)

- Advanced statistical tools (ANOVA, Regression, DOE)

- Multi-voting

- Pilot projects

- Validation studies (statistical tests)

Step 3: SUSTAIN

- Empowering team

- Cost Savings

- Andon flags and lights

- Process and visual controls (QDIP)

- Report Out and Replicate

- Process Management Structure

- Daily continuous improvement

- Sustaining the culture of improvement

Not sure if this is right for you?

1) Watch one of our presentations to become more familiar with the content that will be discussed (but in much more detail!)…

2) Consider taking our 1-hour online course covering the W.A.S.T.E. Walks approach or listen to our free podcast series

3) Check out some of our free templates and guides for download

Logistics

Lunch will NOT be provided. There are numerous restaurants and food carts nearby with a variety of choices, including many international dishes, gluten-free and vegan options.

Travel to Portland

Not from the Portland metro area? Visit TravelPortland.com for help with transportation, hotels and accommodations, sightseeing and tips for getting around town.

Cancellations

You can cancel up to 30 days before the event and get a full refund. However, space is limited, so inside of 30 days you will only get a 50% refund. No shows will not get a refund, so please communicate prior to the class if something goes wrong with your travel plans or you have a personal emergency.

Pricing

Cost is $297 per person, or $197 for early bird signup.

We currently do not have any classes scheduled. If you are interested in this class, consider attending the Lean Six Sigma for Environmental Manager 1-Day workshop at the NWEC conference in Portland on Dec 8, 2016. If you cannot attend, contact us to express interest.

Still not sure? Download our “8 Ways Lean Six Sigma Tools Can Reduce Environmental Impacts” or our list of “20+ Environmental Lean Six Sigma Case Studies”